resources

- Home

- resources

What is Corrugated?

Corrugated fiberboard or “combined board” has two main components: the liner and the medium. Both are made of a special kind of heavy paper called containerboard. Linerboard is the flat material, typically on the outer surfaces of the board but also on the inside for some structures, that adhere to the medium. Medium is the pater that is formed into arches or flutes on the single face and glued between the linerboard facings.

Flutes

Architects have known for thousands of years that an arch with the proper curve is the strongest way to span a given space. The inventors of corrugated fiberboard applied this same principle to paper when they put arches in the corrugated medium. These arches are known as flutes, and when anchored to the linerboard with an adhesive they resist bending and pressure from all directions.

When a piece of combined board is placed on its end, the arches form rigid columns, capable of supporting a great deal of weight. The flutes act to keep the linerboard sheets separated, maximizing the bending rigidity of the board. When pressure is applied to the side of the board, the space in between the flutes act as cushion to protect the container’s contents. The flutes also serve as an insulator, providing some product protection from sudden temperature changes. At the same time, the vertical linerboard provides additional strength and protects the flutes from damage.

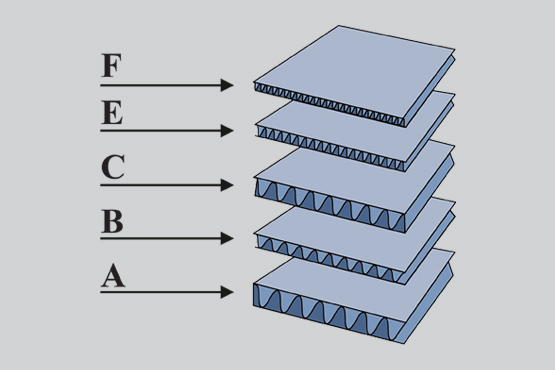

Flutes come in several basic designations. Flutes with the same designation have a similar size, but may use various profiles and number of flutes per foot within a given designation.

⦁ A flute is the original flute profile for corrugated board. It has about 33 flutes per foot and is 3/16” in thickness.

⦁ B flute was then developed for canned goods that were self-supporting, and so did not require boxes that supported much load. It has about 47 flutes per foot and is 1/8” in thickness.

⦁ C flute was next developed as an all-purpose flute, and it has about 38 flutes per foot and is 5/32” in thickness.

⦁ E flute was the next successful flute profile, and it has about 90 flutes per foot and 1/16” in thickness.

⦁ F flute was developed for small folding carton type boxes. It has about 125 flutes per foot and 1/32” in thickness.

In recent years not only has there been a proliferation of flute profiles, but there has been an increase in the variation of flute characteristic measurements for any given flute profile. Flute profiles will vary, sometimes significantly, because the corrugator rolls are manufactured to address a variety of aspects (such as speed, paperboard characteristics, economies, etc.).

Combined Board

The below illustration demonstrates four basic types of combined board that are most commonly created from linerboard and medium using the variety of flute structures:

⦁ Single Face: one corrugated medium is glued to one flat sheet of linerboard.

⦁ Single Wall: the corrugated medium is glued between two sheets of linerboard. Also known as Double Face.

⦁ Double Wall: three sheets of linerboard with two mediums in between.

⦁ Triple Wall: four sheets of linerboard with three mediums in between.

Generally, larger flute profiles deliver greater cushioning and vertical compression strength, while smaller flute profiles provide enhanced graphics capability. Smaller flutes such as E and F also provide enhanced structural capabilities for primary (retail) packaging compared to paperboard (folding cartons). There is a good deal of variance across the industry in the range of flute sizes based upon the container characteristics that are desired for each application.

MULLEN VS ECT

Most industries have a standard for measuring or describing the construction of a particular material. However, in the corrugated industry, there are two standards – the Mullen Test and the ECT (Edge Crush Test). This leads to confusion in the marketplace.

The Mullen Test, which has been used for many years, tests the bursting strength of corrugated board – how much pressure is required to rupture the wall of a piece of corrugated material. Boxes conforming to the Mullen Test standard are identified as 200# Test, 275# Test, etc. The higher the number, the stronger the corrugated box.

The Edge Crush Test, which was developed in the 1990’s, measures the stacking strength of corrugated board – how much top to bottom pressure a box can withstand before crushing. Boxes conforming to the Edge Crush Test standard are identified as 32ECT, 44 ECT, etc. Again, the higher the number, the stronger the corrugated box. For most general-purpose applications, 200# Test and 32ECT are interchangeable; however, the board comprising 200# Test material is slightly heavier than the 32ECT equivalent, making it somewhat more expensive. 32ECT boxes have become extremely popular since the Edge Crush Test was introduced, partly due to cost, and partly because stacking strength is a more meaningful measure of how a box will perform in the field.

Mullen

⦁ Tests the bursting strength of corrugated board –how much pressure is required to rupture the wall of a piece of corrugated material

⦁ Stronger box and better printable surface

⦁ The higher the number, the stronger the corrugated box

⦁ More expensive than ECT

⦁ Most common grades are 200#, 275# and 275#DW

Edge Crush Test (ECT)

⦁ Developed in the 1990′s, measures the stacking strength of corrugated board –how much top to bottom pressure a box can withstand before crushing

⦁ 32ECT boxes have become extremely popular since the Edge Crush Test was introduced, partly due to cost, and partly because stacking strength is a more meaningful measure of how a box will perform in the field

⦁ Most common sizes are 32 ECT, 44 ECT and 48ECT

| Box Strength |

|---|

32ECT |

200# |

44ECT |

275# |

48ECT |

275#DW |

| Description |

|---|

Single Wall Box |

Single Wall Box |

Heavy Duty Single Wall Box |

Heavy Duty Single Wall Box |

Double Wall Box |

Double Wall Box |

| Box Liner Combination |

|---|

35/23/35 |

42/23/42 |

56/23/56 |

69/23/69 |

35/23/35/23/35 |

42/23/42/23/42 |